|

Dear customers and ATENA friends,

we hope you are doing well. We would like to share the latest development in ATENA as the year 2023 progresses.

Maybe you already know from our latest newsletters and announcements we are planning to release the mighty ATENA 2023 with its own pre-processor this year. To bring this version close to perfection, we decided to divide its release into two steps. The first phase will include ATENA 2023 beta which will be published in June 2023. This version will be available for our customers with valid maintenance for testing and evaluation. We would like to encourage you to give us your tips for improvements and fixes. |

|

To explore more about this ATENA 2023 beta, we would strongly recommend you to attend our next webinar on May 30th, where we will be introducing its major capabilities. Registration is available here. The main goal is to create our new pre-processor and to combine the robustness of ATENA Science with simplicity of ATENA 3D Engineering. A standard commercial ATENA 2023 version is supposed to be released in fall 2023.

If you are not sure whether ATENA is suitable for your research or profession, please do not hesitate to download a free trial version for 30 days. It is free of charge and it includes ATENA with full capabilities. You can go through a basic/advanced ATENA modelling within a very short time.

Thank you for your kind attention and see you around on any international events in 2023!

Your ATENA team |

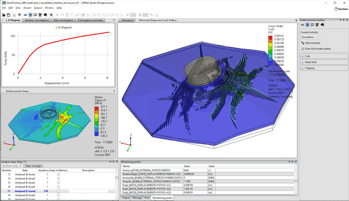

Fig. 1: Results from ATENA analysis of a wind turbine foundation, showing the crack pattern and crack width developement during an extreme vibration event. Nonlinear analysis helps in more efficient design of wind turbine foundations.

|

ATENA Development

|

We are continuously working on expanding the capabilities of our ATENA software. This year we plan to release a brand new version of ATENA preprocessor. The main objective is to bring our standard product ATENA Engineering to a higher level. The official release date of the new version will be this year in September, however the beta version will be available for download in June.

This beta version will be available to our users with a valid maintenance license. We recommend to make sure your maintenance license is valid and active so that you can start using this new version immediately. The new preprocessor in ATENA 2023 will basically replace old 2D and 3D pre-processors for ATENA Engineering. At first it will support only static analysis, but other modules for creep, transport and dynamic will follow soon. The new version will be also compatible with the current Science version, which for the time being will be still used for more advanced analyses such as creep, transport or dynamic. The following list summarizes the main new improvements in the new ATENA 2023 Preprocessor, if compared to the existing ATENA 2D & 3D Engineering: |

ATENA version 2023

- 2D and 3D modelling and preprocessing will be combined into a single environment,

- curved NURBS lines and surfaces will be supported,

- stronger compatibility with ATENA Science,

- import of *.gid models,

- scripting support using Python programming language,

- import of other data formats such as: ifc, iges,

- support for layers as in other modelling programs,

- possibility to develop user defined material libraries as well as materials,

- support for construction process modelling both in 2D and 3D, |

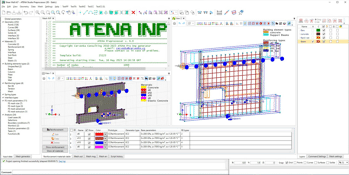

Fig. 2: Overview of the main user interface of ATENA 2023 pre-processor showing the multiple windows for model definition and automatic mesh generation.

|

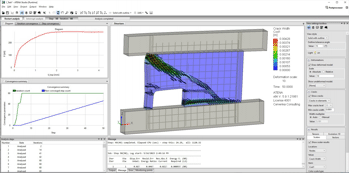

Fig. 3: ATENA 2023 uses ATENA Studio for runtime analysis visualization and post-processing.

|

- durability models for reinforcement corrosion and alkali-silica reaction,

- modelling and simulation of 3D concrete printing,

- BIM based internal data format,

- our popular AtenaStudio program is used for unique runtime visualization and control,

- fully built on 64-bit technology and supporting larger computer memory capacity and speed.

The release of this new version will represent an important step in ATENA history. |

|

Our goal is to gradually combine our Engineering and Science product lines into a single transparent environment allowing users to perform all modelling and simulation in a single, powerfull and user-friendly package.

This first release will replace the original ATENA 2D and 3D programs, which are based on the old 32-bit technology. The new version will allow to fully exploit the current 64-bit computer technology. The compatibility with previous 2D and 3D programs will be preserved, which means that it will be possible to import the old *.cc2 and *.cc3 files.

A first preview of the new ATENA 2023 Pre-processor, which replaces ATENA 2D and 3D Engineering environment you can find here. |

Fig. 4: 3D model of a historical bridge in the environment of the new ATENA 2023 pre-processor.

|

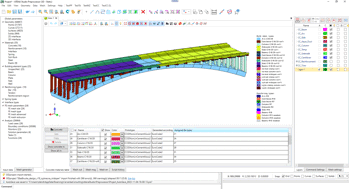

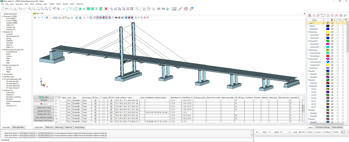

Fig. 5: Large scale 3D model of a composite steel-concrete cable stayed bridge in ATENA 2023 imported from a previous GiD model.

|

ATENA 2023 software was developed with the financial support of the Technology Agency of the Czech Republic within the DELTA 2 Programme project TM01000059 - "Reducing material demands and enhancing structural capacity of multi-spiral reinforced concrete columns – advanced simulation and experimental validation".

Please, make sure your maintenance licence remains valid so that you are entitled to download this new version when it becomes available. Contact our sales representatives (cervenka@cervenka.cz) to be eligible for this new upgrade. |

Success Stories

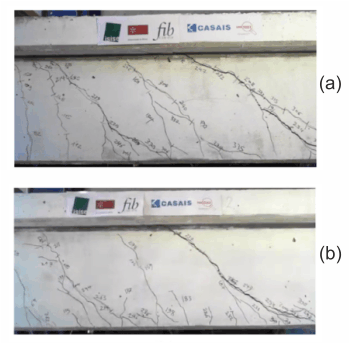

Lessons learnt from blind competition of shear behavior of fiber-reinforced concrete T-beam

by Skadins, U., Cervenka, J., Structural Concrete, February 2023, https://doi.org/10.1002/suco.202201187

The positive effect of fiber-reinforced concrete (FRC) on shear capacity of reinforced concrete beams is well presented in many experimental studies since 1970s. However, as the main effect of fibers is in the cracking stage, it increases the complexity to analyze such structures numerically. With the increased availability of nonlinear finite element analysis software, structural designers are encouraged to use them to solve complex structural problems. In such cases, understanding and correct definition of material laws in cracked stage of FRC structures are crucial. A blind competition was organized by fib WG 2.4.2 to address this issue. It revealed that the numerical predictions of almost all of the participants overestimated the shear capacity of a T-beam subjected to bending. The aim of the current study is to demonstrate critical aspects in the definition of input parameters of FRC analysis. |

Fig. 6: Comparison of experimental and numerical crack patterns: experimental beam 1 (a) and beam 2 (b).

|

Fig. 7: Type 1 (c), Type 2 (d), and Type 3 (e); the simulated figures are mirrored to comply with the photograph.

|

A comprehensive parametric analysis is performed considering tensile softening law, shear stiffness, and shear strength definition in cracked stage as well as shrinkage effects. The results suggest that most important aspect is the correct definition of tensile softening law, which should correspond to the lower bound of residual strength obtained by standard notched prisms tests according to EN 14651 or even smaller.

A comprehensive parametric analysis is performed to simulate load bearing capacity of a FRC T-beam subjected to shear failure using nonlinear finite element software. Based on the comparison between crack patterns and load–deflection behavior of the numerical models and the experimental results the following main conclusions can be drawn:

- To simulate shear capacity of a FRC beam, it is necessary to use such material laws that correspond to the lower bound of residual strength obtained by standard prism tests. However, for better results, prism tests with orientation of fibers similar to the application case should be used.

|

- Current analysis attests the recommendation by fib Model Code 2010 that the first part of tensile softening law of FRC should comply with the softening law of plain concrete.

- It is important to consider the effects induced by shrinkage of concrete if stiffness of a reinforced FRC beam must be predicted precisely.

- It seams that the approach to relate shear parameters like shear stiffness and shear strength to tensile softening law is reasonable. However, an experimental study is needed to calibrate the models for FRC.

|

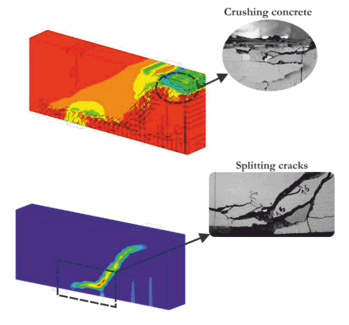

Moment Transfer at Column-Foundation Connections: Analytical Studies

by Benjamin L. Worsfold and Jack P. Moehle, ACI Structural Journal/March 2023, title No. 120-S39

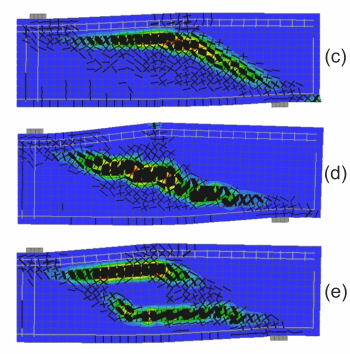

This paper describes finite element (FE) models of concrete anchors built using the software ATENA and calibrated with physical test data from Ninčević et al. (2019), Gaspar and Moehle (2021), and Worsfold et al. (2022). |

Fig. 8: FE model for Specimens M01 and M02 and test setup.

|

Fig. 9: Physical specimen cross section and FE blind prediction crack patterns for monotonic loading in each direction with reinforcement overlaid.

|

FE parametric studies were performed with the calibrated models to investigate critical variables affecting the failure modes of concrete breakout and beam-column joint (BCJ) failure. The beneficial influence of shear reinforcement on the breakout failure was investigated, as well as requirements for placement and development of the reinforcement. A series of physical tests was used to calibrate finite element (FE) models of cast-in-place anchors for single anchor axial tests, anchor group axial tests, and anchor group moment tests. Modeling guidelines developed from the calibrations were used to perform a blind prediction of another group anchor moment test (Specimen M02). The calibrated results and the blind prediction adequately matched the observed strengths, displacements, crack patterns, and shear reinforcement strains. |

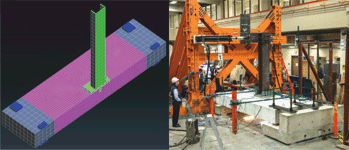

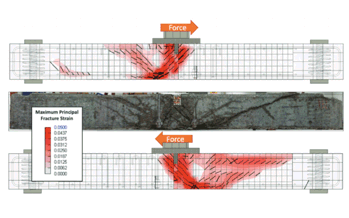

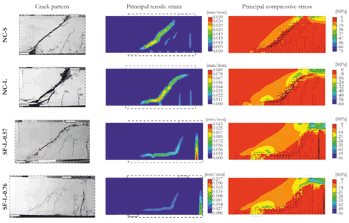

Ultimate capacity prediction of RC and SFRC beams with low shear span-depth ratio using NLFEA and inverse analysis

by Benedetty, C.A.; Irreño, I.R.; Martinez, J.J.; Almeida, L.C.; Trautwein, L.M.; Krahl, P.A., Revista de la Construcción. Journal of Construction, 21(3), 717-736, (2022). https://doi.org/10.7764/RDLC.21.3.717

In this study, the capacity and ultimate behavior of Reinforced Concrete (RC) and Steel Fiber Reinforced Con-crete (SFRC) beams are evaluated. |

Fig. 10: Experimental and numerical crack patterns, principal tensile strains and principal compressive stresses

|

Fig. 11: Localized fractures - crushing concrete in SF-L-0.57 beam and horizontal splitting cracks in NC-L beam

|

FE modeling guidelines were distilled and used to perform a blind prediction of a full-scale column-foundation connection by Worsfold et al. (2022). Nonlinear Finite Element Analysis (NLFEA) and the inverse analysis technique were used to model its structural response using the ATENA finite element software.

The smeared crack approach, the crack band model, and advanced constitutive models were used to reproduce concrete fracture. The analyzed beams were subjected to rupture in a four-point bending test setup.

The relationship between the shear span and the depth of the beams was 1.5. Four scenarios were analyzed, RC beams with and without stirrups, and SFRC beams without stirrups with volumes of 0.57% and 0.76%. The results obtained in the modeling are discussed in terms of the ability of the models to numerically reproduce the relationships: load versus displacement, load versus strain, crack patterns, and failure modes.

The analysis techniques allowed to reproduce the experimental response of the beams with good agreement. They show great potential to solve structural engineering problems. |

ATENA Webinars

|

Planned webinars:

May 30th, 2023: Introduction to new ATENA 2023 Preprocessor

Registration is available here.

A first preview of the new ATENA 2023 Pre-processor, which replaces ATENA 2D and 3D Engineering environment you can watch here.

June 2023: Modelling of cycling and dynamic loading in ATENA Science

All past webinars you can find here. |

Fig. 12: Screen of the 2/February 2023 webinar (Overview and theoretical background of ATENA material models)

|

Where You Can Meet Us

|

May 25-26, 2023

Conference Modelling in Mechanics

Velke Losiny, Czech Republic

Event website

June 5-7, 2023

fib Symposium

Istanbul, Turkey

Event website

June 11-15, 2023

International Symposium

on Life-Cycle Civil Engineering

Milano, Italy

Event website

June 20-22, 2023

BetonTage

Ulm, Germany

Event website

June 21-23, 2023

CFRAC 2023

Prague, Czech Republic

Event website

September 10-14, 2023

IA-FraMCoS

Bangalore, India

Event website

September 20-22, 2023

IABSE Congress 2023

New Delhi, India

Event website

October 29-November 2, 2023

ACI Fall Convention

Boston, MA, USA

Event website

November 7-8, 2023

Concrete Days

Hradec Kralove, Czech Republic

Event website

|

Fig. 13: Jan Cervenka at ATENA exhibition booth during ACI Concrete Convention 2023, San Francisco, CA, USA

|

Recent ATENA Articles

|

BARROS, J., SANZ, B., FILHO, M., FIGUEIREDO, F., KABELE, P., YU, R.C., MESCHKE, G., PLANAS, J., CUNHA, V., CAGGIANO, A., OZYURT, N., GOUVEIA, V., van den BOS, A., POVEDA, E., GAL, E., CERVENKA, J., NEU, G.E., ROSSI, P., DIAS-DA-COSTA, D., JUHASZ, P.K., CENDON, D., RUIZ, G., VALENTE, T., Blind Competition on the Numerical Simulation of Continuous Shallow Steel-fiber Reinforced Concrete Beams Failing in Bending, Structural Concrete, fib, https://doi.org/10.1002/suco.202200754

BENEDETTY, C.A.; IRRENO, I.R.; MARTINEZ, J.J.; ALMEIDA, L.C.; TRAUTWEIN, L.M.; KRAHL, P.A., Ultimate Capacity Prediction of RC and SFRC Beams with Low Shear Span-depth Ratio using NLFEA and Inverse Analysis, Revista de la Construcción. Journal of Construction, 21(3), 717-736, (2022). https://doi.org/10.7764/RDLC.21.3.717

NOVAK, D., PUKL, R., Advanced Integrated Assessment of Concrete Bridges Considering Nonlinearities, Uncertainties and Degradation, Structural and Physical Aspects of Construction Engineering - SPACE 2022, October 12-14, 2022, Strbske Pleso, High Tatra, Slovakia, https://space.uis.svf.tuke.sk

JENDELE, L., RYMES, J., CERVENKA, J., Optimizing Digital 3D Printing of Concrete Structures, Rilem Week 2023, Vancouver, BC, Canada, Sept. 4-8, 2023

CERVENKA, V., RIMKUS, A., GRIBNIAK, V., CERVENKA, J., Uncertainty of the Crack Width Model Based on Fracture of Concrete, Eurostruct 2023

CERVENKA, J., RYMES, J., Digital Twin for Modelling Structural Durability, In: RILEM International Conference on Numerical Modeling Strategies for Sustainable Concrete Structures. Springer, Cham, 2023. p. 79-89, DOI 10.1007/978-3-031-07746-3_8

CERVENKA, J., RYMES J., Is Nonlinear Analysis becoming a Standard Tool for Design of Concrete Bridges?, Accelerated Bridge Construction International Conference, Miami, USA, 7-9.12.2022

CERVENKA, J., RYMES, J., JENDELE, L., PUKL, R., Digital Twins for Reinforced Concrete Structures, fib Symposium, Istanbul 2023, June 5-7, 2023

CERVENKA, J., RYMES, J., PUKL, R., Nelineární analýza a simulace jako nástroj pro navrhování a posuzování železobetonových mostů, konference Mosty 2023, 20-21.4.2023

CERVENKA, J., SKANDIS, U., Lessons Learnt from Blind Competition of Shear Behavior of Fiber-reinforced Concrete T-beam, DOI: 10.1002/suco.202201187, Structural Concrete. 2023; 1–20

RYMES, J., CERVENKA, J., Simulation of 3D-Printed Concrete Structures, Accelerated Bridge Construction International Conference, Miami, USA, 7-9.12.2022

WORSFOLD, B.L., MOEHLE, J.P., Moment Transfer at Column-Foundation Connections: Analytical Studies, ACI Structural Journal/March 2023, title No. 120-S39 |

|